RESOURCE

Lithium-ion Battery

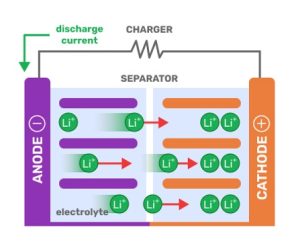

A lithium-ion (Li-ion) battery is a rechargeable battery which consists of four main components: anode, cathode, separator, and electrolyte.

| During charging | During discharging |

When the battery charges, the lithium-ions move from positive electrode (cathode) to negative electrode (anode) through electrolyte.

| When the battery discharges, the lithium-ions stored in the anode flow back to the cathode, thus energy is used.

|

Reference:

- Chapman, B. (2019, September 23). How Does A Lithium-Ion Battery Work? Let’s Talk Science.

- Forbes, J. (2019, December 23). How Does A Lithium-ion Battery Work? Flux Power. lithium-ion-battery-work

- Brain, M. (2021, November 3). How Lithium-ion Batteries Work. HowStuffWorks.

- Unwin, J. (2019, May 15). What Are Lithium Batteries and How Do They Work? Power

No. There are various types of lithium-ion batteries in the market such as Lithium Iron Phosphate (LFP), Lithium Nickel Manganese Cobalt Oxide (NMC), Lithium Cobalt Oxide (LCO) and etc. However, each kind of lithium-ion battery has its own feature and trade-offs between lifespan, cost and safety. Make sure you get the right one!

Reference:

- Forbes, J. (2019a, November 27). Lithium-ion Battery Materials and Why Their Chemistry Matters. Flux Power.

- Battery University. (2022, March 3). BU-205: Types of Lithium-ion.

As compared to other types of batteries, LFP has high ratings in these characteristics. LFP has longer life cycle, great thermal and chemical stability, high safety level and yet comes at a low cost.

Reference:

- Frith, L. (2021, October 27). A Closer Look at Lithium Iron Phosphate Batteries, Tesla’s New Choice of Battery. News.

- Nuamah, C. (2022, January 5). A Simple Comparison of Six Lithium-ion Battery Types.

State of charge (SOC) indicates the percentage of the battery that is currently available relative to its capacity, while depth of discharge (DOD) denotes the percentage of battery that has been discharge. DOD is the inverse form of SOC. For example, if a 100AH battery has been used for 30%, which means its DOD is 30% and SOC is 70%.

Reference:

- S. (2019, October 15). Tech Tuesday: Depth of Discharge, State of Charge & Capacity. RELiON Batteries.

- Abdi, H., Mohammadi-ivatloo, B., Javadi, S., Khodaei, A. R., & Dehnavi, E. (2017, May 24). Energy Storage Systems. ScienceDirect.

A lithium-ion battery is designed to last for at least 3000 charging cycles and still guaranteed 80% of their original capacity. While a lead acid battery only lasts for 1200 to 1500 cycles if maintained well. For lithium-ion battery, one charging cycle is considered to be the complete charge and discharge of the battery. Unlike lead acid battery, every plug-in & out considered as one charging cycle.

Reference:

- Williams Machinery. (2021, October 27). Everything You Need to Know About Electric Forklift Batteries.

- Kenley, J. (2017, September 21). Lithium Ion Forklift Batteries: What You Need to Know. Toyota Material Handling Northern California.

- Sensata Technologies. (2021, September 29). Lead-Acid or Lithium-Ion Batteries? These Things Should Be Considered. LiTHIUM BALANCE.

Multiple Shift vs Single Shift Operation

If your company is having multi-shift operation, we will strongly recommend lithium-ion battery as the solution. This is because lithium-ion battery offers advantages of fast charging (2 to 3 hours to be fully charged) and opportunity charging (can be charged at any idle time like during lunch time or break between the shifts), making it possible to have only 1 battery per truck yet save time for no battery changeout. Unlike lead acid battery, it requires 8 to 10 hours to be full charged, followed by approximately 8 hours of cooling time, which in total of 16 hours. As a result, at least 2 lead acid batteries are required for multi-shift operation and battery change need to be carried out between the shifts.

Battery Life Cycle

Lithium-ion battery has a longer lifespan than lead acid battery. In average, lead acid battery lasts for 1200 to 1500 cycles, however, lithium-ion battery has at least the doubled of lead acid battery cycle which is at minimum 3000 cycles. On the other hand, if you charge lead acid battery for 30 minutes, that considers as one charging cycle, this action will shorten the lifespan of lead acid battery. Whereas, for lithium-ion, it counts as one charging cycle when it gets 100% charged.

Maintenance

For lead acid battery, it requires maintenance such as battery watering, equalization and acid adjustment. However, for lithium-ion battery, it eliminates the need of maintenance. As a result, it would definitely help to reduce labor cost, maintenance cost and yet save time for operation.

Safety

Lithium-ion battery is much safer if compared to lead acid battery. Reason being is lithium-ion battery is fully sealed and it does not require to open for battery watering, reducing the danger of acid spills, toxic fumes as in the case of lead acid battery. Apart from that, lead acid battery may produce explosive gases during charging, which could pose health and safety hazard to the workers. Lithium-ion battery could eventually remove these hazards.

Reference:

- W. (2021, December 15). Why Investing in Lithium-Ion Over Lead Acid Is Advantageous? EFORKLIFT.

- A. (2021a, May 3). Why Change from A Lead-Acid Battery to A Lithium Battery? Flash Battery.

- Metaye, R., PhD. (2022, January 20). Lead-Acid vs Lithium-Ion (10 Key Differences). Climatebiz.

- Hinz, P. (2021, April 16). Comparison: Lithium Ion VS Lead Acid Forklift Batteries. Adaptalift.

- Cummins Inc. (2019, June 17). Spot the Difference: Lithium Ion Versus Lead Acid Battery Electric Technology.

- D’Amato, M. (2021, September 18). Why You Should Consider New Lithium-Ion Batteries for Your Lift Truck. OneCharge.

As you all know, the weight of battery acts as the counterweight in electric truck. In term of weight, lithium-ion battery is much lighter than lead acid battery. However, an additional counterweight, normally a ballast will be added to compensate the weight loss, achieving the required battery weight specification.

Reference:

- Hirschberg, R. (2020, October 20). Advantages & Disadvantages of Lithium Batteries for Electric Forklift Applications | Alpine Power Systems Blog. Alpine Power Systems.

- Writer, S. (2021, June 26). The Truth About Lithium Ion Batteries for Forklifts. Warehouse IQ.

Definitely yes. Retrofitting lead acid battery to lithium-ion battery is a very simple and quick process. Just provide the forklift model, battery weight, size and working duration to the battery experts, they will advise accordingly based on the requirement. Besides, installation of lithium-ion battery is as easy as swapping out of lead acid battery.

Reference:

- Crown Publications. (2020, September 28). Li-Ion Batteries: The Cost-Effective Retrofit.

- BSLBATT. (2021, September 18). How to Replace Electric Forklift Lead-Acid Battery with Lithium Battery?

Once you do the TCO calculation, the answer will be yes. Although lithium-ion battery has a high upfront cost, the advantages of lithium-ion well worth the cost such as longer lifespan, efficient charging, no daily maintenance and safer operation.

Reference:

- Ansley, H. (2020, October 23). Are Lithium-Ion Forklift Batteries Worth the Price? Two Surprising Stats. Mid-Columbia Material Handling, Inc.

- D’Amato, M. (2021b, September 18). Why You Should Consider New Lithium-Ion Batteries for Your Lift Truck. OneCharge.

- Kenley, J. (2017b, September 21). Lithium Ion Forklift Batteries: What You Need to Know. Toyota Material Handling Northern California.

Lithium-ion battery does not require a charging room to house the chargers and spare battery like what lead acid do. However, since lithium-ion battery has much faster charging speed, it requires a higher current input. Therefore, you need to check the existing power supply of infrastructure. You may upgrade your electrical supply for efficient charging and it would be only one-time cost.

Reference:

- Westerra Equipment. (2021, October 29). Forklift Battery Sizing and Technology Guide (Lithium-ion vs Lead-acid).

- J, P. A. (2022, March 18). Forklift Battery Types: Function, Advantages, and Disadvantages. Reseach Dive.