SOLUTIONS & TECHNOLOGIES

Material Handling Equipment (MHE)

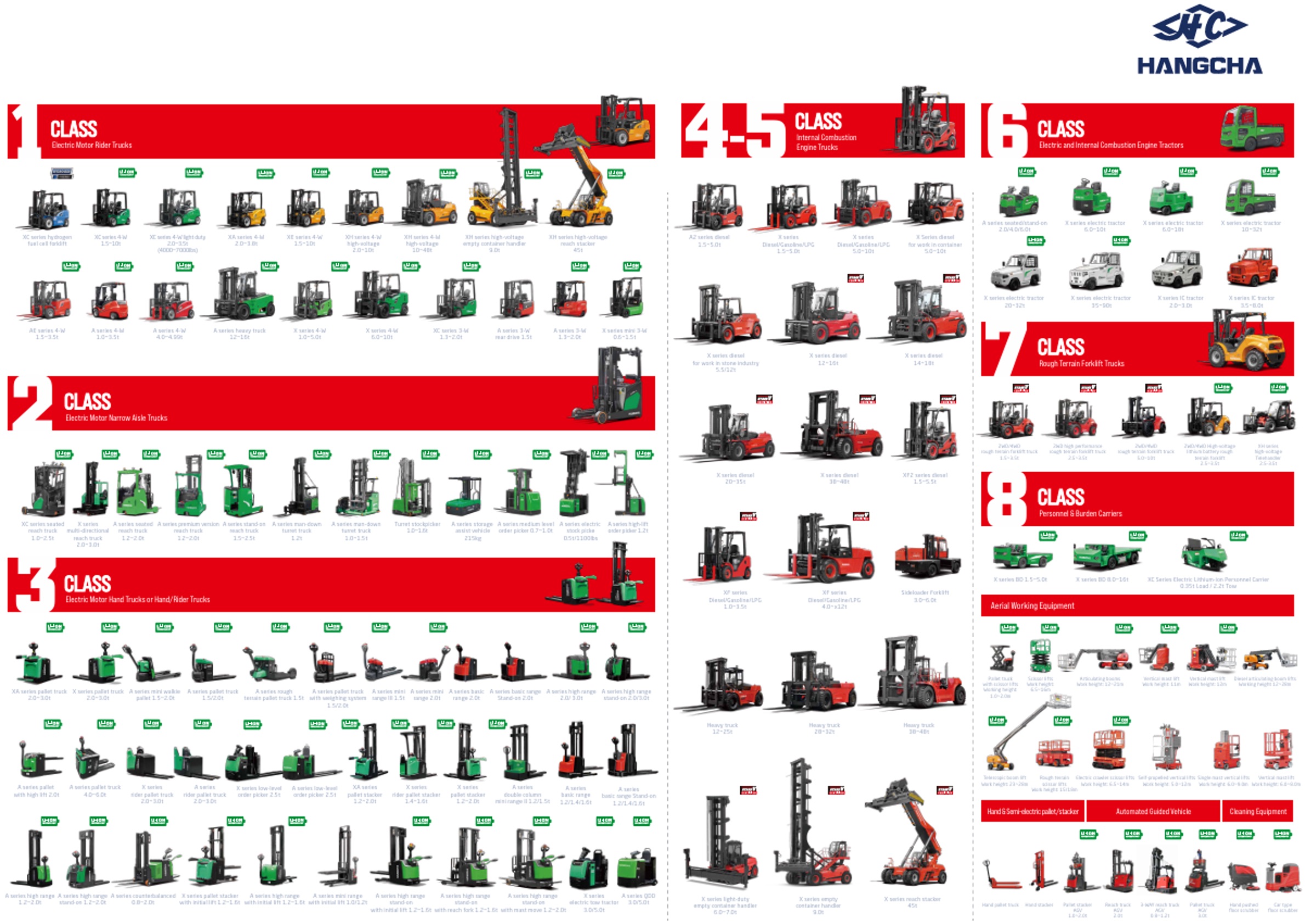

As an official distributor of Hangcha, we are proud to offer a wide range of their high-quality material handling equipment — known globally for durability, innovation, and value for money. Hangcha has over 60 years of experience in industry and ranks among the world’s leading manufacturers of material handling equipment.

Whether you're managing a high-volume warehouse, manufacturing facility, or logistics hub, Hangcha’s solutions are engineered to deliver reliable performance, advanced ergonomics, and cost-effective operation.

To help you choose the right equipment for your operation, we categorize our offerings according to standard industrial truck classifications.

Industrial Truck Comparison

CLASS I – ELECTRIC MOTOR RIDER TRUCKS

Class I trucks are electric-powered counterbalance designed for operators to ride on while driving. They are known for being environmentally friendly, quiet, and energy efficient.

Key equipment includes:

• 3-wheel electric forklifts, which offer superior maneuverability for tight warehouse spaces.

• 4-wheel electric forklifts, which provide more stability for heavier lifting and higher stacking.

• High-voltage lithium models, which provide faster charging and longer operating hours.

CLASS II – ELECTRIC NARROW AISLE TRUCKS

Class II trucks are designed to operate efficiently in narrow aisles and high-density racking systems. They are electric-powered and specialized for environments where space is limited but vertical storage is maximized.

Key equipment includes:

• Reach trucks, which have extendable forks that can reach deep into pallet racks.

• Order pickers, which lift both the operator and load for manual picking from elevated racks.

• VNA trucks (also called turret trucks), which rotate the forks 180 degrees without turning the truck, perfect for very narrow aisles.

CLASS III – ELECTRIC PALLET TRUCKS & STACKERS

Class III covers electrically powered equipment used primarily for horizontal pallet movement and low-level stacking. They are typically operated by walking behind the truck (walkie) or riding on it (rider).

Key equipment includes:

• Walkie pallet trucks, which are ideal for moving pallets short distances in compact spaces.

• Rider pallet trucks, suited for longer runs in larger facilities.

• Walkie stackers, which allow for basic vertical stacking in tight storage areas.

• Straddle stackers, designed to handle wider pallets without hitting racking legs.

• Platform stackers and light-duty tow tractors for indoor material movement.

CLASS IV & V – INTERNAL COMBUSTION (IC) ENGINE TRUCKS

Class IV – IC Forklifts with Cushion Tires

Class IV forklifts are powered by internal combustion engines (LPG, gasoline, or diesel) and equipped with cushion tires, which are solid rubber and best suited for smooth, indoor floors. These forklifts are valued for their power and compact turning capabilities in indoor industrial settings.

Key equipment includes:

• LPG-powered counterbalance forklifts, popular for their quick refueling and strong lifting power.

• Diesel/ gasoline forklifts with cushion tires, for heavier lifting on factory floors.

• Compact IC cushion forklifts, designed for tight warehouse or production line maneuvering.

Class V – IC Forklifts with Pneumatic Tires

Class V forklifts also run on internal combustion engines but are fitted with pneumatic tires, which can be air-filled or solid. These tires provide better traction and cushioning, making the equipment suitable for both indoor and outdoor use, including rough or uneven surfaces.

Key equipment includes:

• Diesel counterbalance forklifts, capable of heavy lifting and outdoor operations.

• LPG forklifts with pneumatic tires, for mixed indoor/outdoor environments.

• Heavy-duty forklifts, handling loads of 10 tons or more.

• Outdoor high-mast forklifts, for high stacking in open yards.

CLASS VI – TOW TRACTORS

Tow tractors are not lifting machines but are designed to pull loads on trailers or carts. These vehicles are either electric or combustion-powered and serve in environments that require high-volume towing over long distances.

CLASS VII – ROUGH TERRAIN FORKLIFT TRUCKS

Class VII forklifts are engineered for challenging outdoor environments, where durability, traction, and lifting power are critical. Designed with large, deep-tread pneumatic tires, they provide superior stability and control on uneven ground, gravel, mud, and soft surfaces.

Traditionally powered by diesel, Class VII forklifts are now also available in advanced lithium-ion (Li-ion) versions, offering eco-friendly performance, reduced operating costs, and quieter operation without sacrificing power.

Key equipment includes:

• Rough terrain forklifts with 2WD or 4WD options for off-road hauling.

• Telehandlers (telescopic handlers) with extendable booms for reaching high or hard-to-access locations.

CLASS VIII – PERSONNEL & BURDEN CARRIERS

These vehicles are designed for transporting people or materials across large facilities or campuses. Most are electric-powered and are highly customizable for different tasks.

AERIAL WORKING EQUIPMENT (AWE)

Aerial Work Equipment (AWE) series is engineered to deliver safe, stable, and efficient access to elevated work areas. Designed with operator safety and productivity in mind, these machines are ideal for maintenance, installation, warehousing, and construction tasks that require reliable vertical reach and maneuverability.

Product Types Include:

• Scissor Lifts, ideal for vertical lifting of personnel and tools.

• Articulating Boom Lifts, provide up-and-over reach for hard-to-access areas. Suitable for facilities maintenance, exterior repairs, or tree trimming.

• Telescopic Boom Lifts, offer extended horizontal outreach, perfect for large construction sites or industrial facilities with wide work zones.

• Vertical Mast Lifts, compact, lightweight platforms for tight indoor spaces such as warehouses and retail settings.

HAND & SEMI-ELECTRIC PALLET TRUCKS AND STACKERS

For businesses looking for cost-effective, compact, and efficient solutions for material movement, our range of Hand and Semi-Electric Pallet Trucks and Stackers offers the perfect balance between manual control and powered assistance.

AUTOMATED GUIDED VEHICLE (AGV)

AGVs are intelligent, driverless systems designed to automate material movement in warehouses and production environments. Built on reliable equipment platforms, these AGVs offer precise navigation, smart fleet coordination, and 24/7 operation — improving safety, reducing labor costs, and enhancing productivity in modern intralogistics.

CLEANING EQUIPMENT

As part of its expanding product portfolio, we offer a line of high-performance cleaning equipment designed to maintain safe, clean, and efficient industrial environments.

After

After

Before

Before