SOLUTIONS & TECHNOLOGIES

Lithium Battery Retrofit Solutions

We help businesses upgrade their existing material handling equipment by replacing conventional lead-acid batteries with high-performance lithium-ion battery systems. This retrofit not only enhances equipment performance but also contributes to significant long-term cost savings and sustainability goals.

Our lithium retrofit solutions are compatible with a wide range of MHE brands and models, offering:

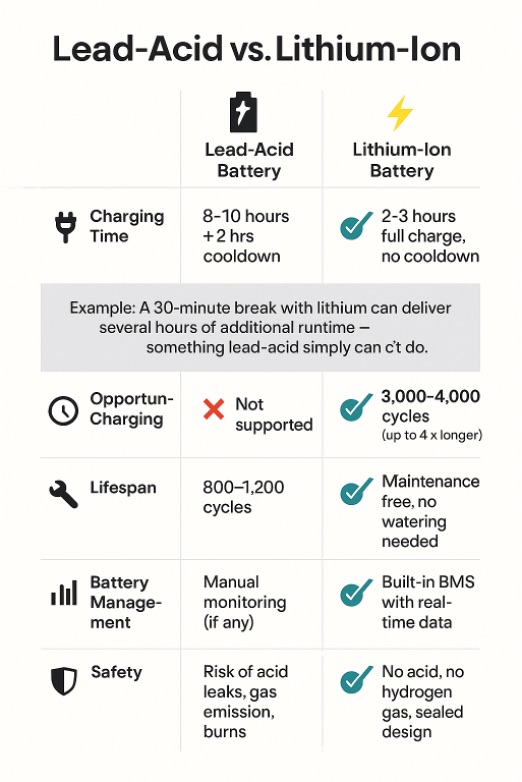

LEAD ACID vs. LITHIUM-ION

The diagram below is for illustration purposes only. Use the information from the table for the content.

| Lead Acid Battery | Lithium-Ion Battery | |

| Charging Time | 8-10 hours | 2-3 hours |

| Opportunity Charging | Not supported | Supported, Example: A 30-minute lithium battery charge can deliver several additional hours of runtime. |

| Lifespan | 800-1200 cycles | 3000-4000 cycles |

| Maintenance | Requires watering, acid handling, equalization charging | Virtually maintenance free |

| Battery Management System | Requires external devices | Built in with real time data |

| Safety | Risks of acid leaks, gas emissions | Fully sealed, no corrosive acid and emit no hydrogen gas during charging. |

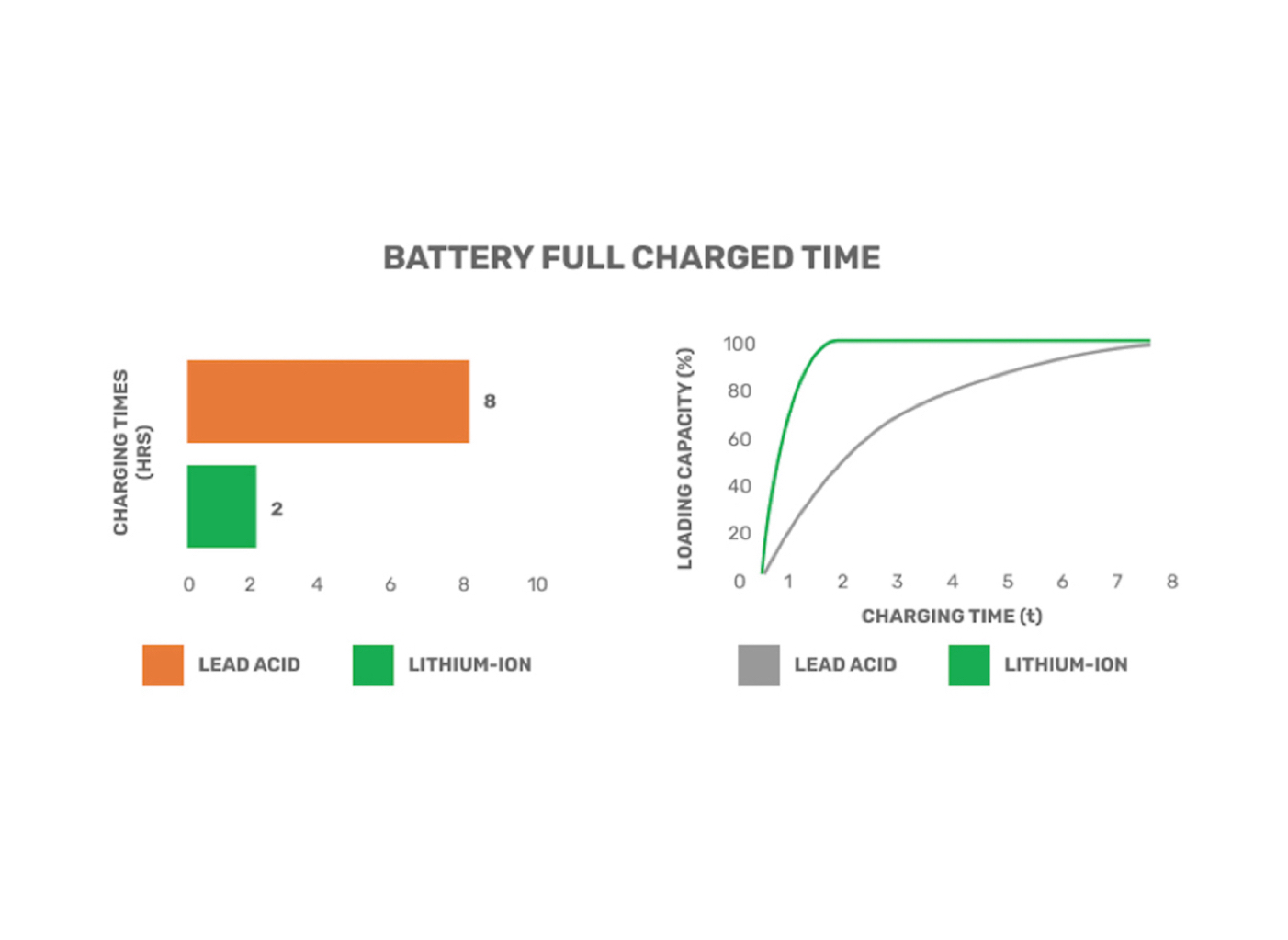

⚡FASTER CHARGING WITH

OPPORTUNITY CHARGE CAPABILITY

Lithium-ion batteries support rapid charging, typically requiring only 2 to 3 hours for a full charge — without the need for a cooling-down period. In comparison, lead-acid batteries require 8 to 10 hours of charging plus additional cooling time, which limits operational flexibility.

Thanks to opportunity charging, operators can conveniently recharge the Lithium-ion battery during short breaks or idle periods — eliminating the need for full charge cycles and maximizing equipment availability throughout the day. For example, a 30-minute break can provide several hours of additional runtime.

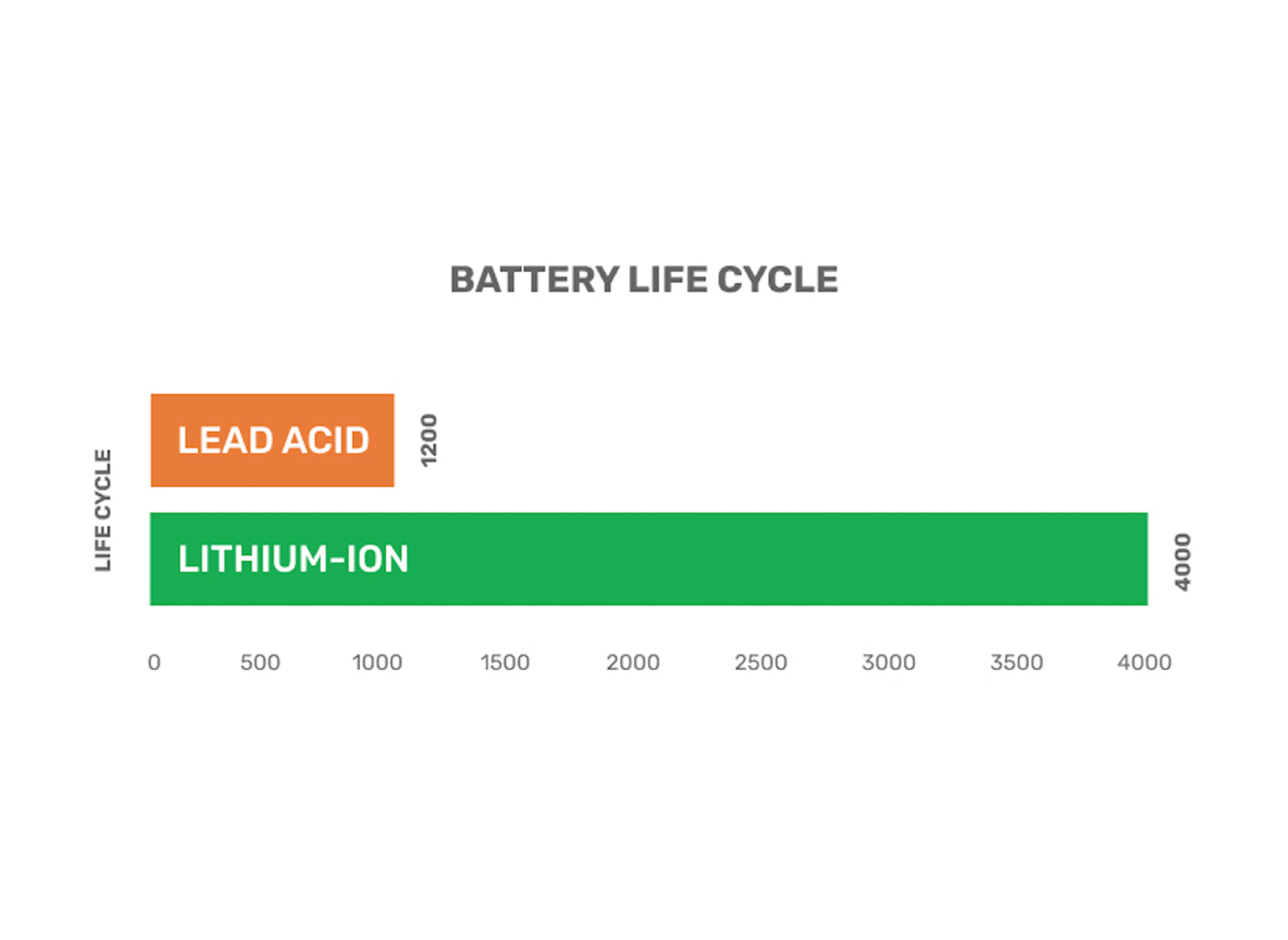

🔄 LONGER LIFESPAN

(UP TO 4X COMPARED TO LEAD-ACID)

Lithium-ion batteries typically last 3,000–4,000 charging cycles, compared to just 800–1,200 for traditional lead-acid batteries.

This extended lifespan reduces the frequency of replacements and lowers the total cost of ownership over time.

🛠️ VIRTUALLY

MAINTENANCE FREE

Unlike lead-acid batteries, lithium-ion batteries are nearly maintenance-free.

There’s no need for watering, acid handling, or equalization charging, which minimizes labor effort, reduces safety risks, and ensures cleaner work environments.

📊 INTEGRATED BATTERY MANAGEMENT SYSTEM (BMS)

FOR REAL-TIME MONITORING

Each lithium-ion battery is equipped with an advanced Battery Management System (BMS) that continuously monitors voltage, temperature, current, and charge status.

The BMS provides real-time diagnostics, enhances safety, and ensures consistent performance throughout the battery’s lifecycle.

🛡️SAFER OPERATION

Lithium-ion batteries are fully sealed units that contain no corrosive acid and emit no hydrogen gas during charging. This design eliminates the common safety hazards associated with lead-acid batteries — such as acid leaks, chemical burns, and flammable gas accumulation — ensuring a cleaner, safer, and more compliant operating environment for both personnel and facilities.

ONLY 3 SIMPLE STEPS TO UPGRADE TO LITHIUM-ION BATTERIES

Consultation & Compatibility Check

Get in touch with us. Our specialists will assess your forklift model and operational requirements to ensure the correct lithium battery type, size, and specifications for a seamless upgrade.

Plug & Play Installation

We remove the existing lead-acid battery and install the new lithium-ion unit — no major modifications needed. Our systems are designed for straightforward integration with most MHE brands and models.

Test & Go

Once installed, we run safety checks and functionality tests. You’re ready to operate immediately — with faster charging, zero maintenance, and long-term energy efficiency.