FAQs

Material Handling Equipment (MHE)

Industrial Truck | Description |

Counterbalance truck

| Known as forklift. It is designed with a counterweight at the rear of the truck to offset the load to be lifted at the front. It carries out the function of loading, stacking and horizontal transporting. |

Pallet truck

| Pallet truck has a very low height lift, which normally not more than 200mm. Therefore, it is suited for goods handling at ground level and transporting pallet-loads from point to point. |

Stacker

| Stacker is very similar in look to pallet truck but with addition of mast which allows to move the loads vertically up to 5m generally. In other words, it is used for horizontal movement of pallet-loads and also for vertical stacking. |

Reach truck

| The usage of reach truck is next stage up from stacker. Its whole mast can be moved forward and backward with the load. As compared to stacker, it is capable to handle heavier load and greater height (up to 12m). |

Order picker

| Order picker is used to pick individual items from the racking then transfer them to the pallet. It is available in low- and high-level picking which ranges from ground level to 12m height. |

Very narrow aisle (VNA) truck

| VNA is suited for operation that has to stack and pick at extreme height and very narrow working aisle. |

Tow tractor

| Tow tractor is designed to pull or tow other equipment like trailers and cages over horizontal distances. |

Reference:

- Vaughan, V. (2021, February 25). What is a Pallet Truck Used For? Manutan UK Blog.

- Nopper, N. (2020, August 17). The Uses of Forklifts, and Why You Need One. Lakeport Metalcraft Inc.

- Fayolle, D. (2016, October 20). Expo Permanente. Industry Plaza.

- SFS Equipments. (2022, February 8). Reach Truck.

- Williams, K. (2017, October 5). What are the Different Types of Tow Tractors? Warehouse Machine.

Since there are different types of industrial truck and each one is designed to be used for different operation, thus there are several important factors to consider when choosing a right truck:

Business Nature

Different business nature will influence the truck selection. For example, for food and beverages industry, electric truck is strongly recommended to use in the warehouse. Reason being is electric truck does not emit poisonous gases and black soot which can affect the food quality as what diesel or LPG truck does.

Task Required

To choose an industrial truck, you need to know what is the task going to carried out. For instance, if your operation is required to do only horizontal transporting from point A to point B (ground level), then you will only need a pallet truck. However, if your operation requires both horizontal and vertical movement, then you might need to consider either stacker, reach truck or VNA, depending on the aisle width and lifting height.

Load Size and Capacity

To choose the truck capacity that meet your requirement, it is important to look at:

- What is the dimension of load?

The load dimension will determine the length of fork required. The longer the load, the farer the load centre, thus the lower the lifting capacity.

- What is the heaviest load you carrying?

The truck capacity should at least meet the maximum load weight. As a reminder, the higher the load is lift, the lower the lift capacity.

- What is the good you handling?

The load type also matters where there are special attachments to be installed on the truck to enhance the operation. For instance, if your product type is paper rolls, then paper roll clamp has to be installed on the truck to ease your operation.

Height and Aisle Width

In order to determine the suitable mast height, it is essential to ask yourself the following questions:

- What is the highest lifting height?

Make sure the mast chosen is able to reach the required lifting height.

- Are there any height restrictions (door, ceiling, lighting, piping)?

If the truck is required to move underneath a fixed height structure, for instance, do loading and unloading in container, the closed height of the mast is a must to take into consideration.

- What is your aisle width?

With lifting height and aisle width requirements, it will greatly assist you to choose the right type of truck. For example, if your lifting height is around 9m with aisle width of 3.3m, then reach truck will be your choice.

Floor Condition

We need to consider the floor surface and condition to determine the tire selection. 2 questions to choose the suitable tire:

- Where will you be driving the truck? Indoor or outdoor?

- What type of surface will you be driving on? Smooth or rough?

If your truck is driven at outdoor on asphalt or large-stone gravel, air pneumatic tires will be the choice where they provide a smoother and softer ride to you as compared to solid tire. On the other hand, if your working area is having lots of sharp objects like metal, nails on the floor, solid tires will be your best choice since they are puncture-proof.

Usage

Truck usage will help you to determine which way will be more cost effective for you. For example, if your usage is very low, then you may consider used truck where help you to reduce the upfront cost.

Reference:

- Welch, A. (2022, March 17). Essential Factors to Consider When Buying A Forklift. E-Architect.

- Ansley, H. (2020, February 6). 7 Things to Consider Before You Buy A Forklift. Mid-Columbia Material Handling, Inc.

- Granite Industrial. (2018, August 27). Fork Lift FAQ’s and Information from Granite Industrial Forklift Trucks.

- Hinz, P. (2014, August 6). Forklift Selection – Choosing the Right Forklift for Your Business. Adaptalift.

- Cheng, E. (2021, April 13). What are Cushion Tires, Pneumatic Tires, And Solid Pneumatic Tires, and Which is Right for Me?

- Forklift Select. (2019, December 28). The Difference Between Pneumatic Tire Forklifts and Cushion Tire Forklifts.

- CITrucks. (2019, July 29). Pneumatic Tires or Cushion: How to Choose the Right Tire for Your Forklift | Carolina Industrial Trucks.

- Williams Machinery. (2020, April 2). 7 Questions To Ask When Buying a Forklift.

No. Only truck with container specification able to go into container. A truck with “container specification” means the truck able to operate inside a standard shipping container. Normally, the container mast is 3 stages with free lift. When the mast is fully collapsed, the closed height will be less than 2200mm which allows you to drive the truck into the container and, with free lifting feature, you able to pick up the pallet-load inside the container without the height-restriction of the container roof being a concern as the forks can be raised without immediately protruding the inner mast channels.

Reference:

- Trusnik, K. (2021, September 29). What is Forklift Free Lift? Toyota Forklifts.

- Hinz, P. (2020, October 16). How to Choose the Correct Forklift Mast. Adaptalift.

- Selka Forklift. (2021, July 27). What is a Container Mast Forklift?

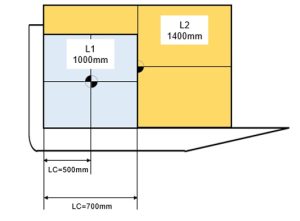

If you have different load dimensions in your warehouse, then you must alert on the lifting capacity. Reason being is different load depth dimensions give different load centres. The lifting capacity will be decreased if your load centre is farer from the fork face. So, what does load centre actually means? Load centre is the distance from the centre of gravity of the load to the edge of the load along the fork. In short, load centre is calculated by dividing the load length by two. As an example, if you have a load weighs 1000kg and 1000mm long, the load centre is 500mm; but by having the same load weight but 1400mm long of load, the load centre will now become 700mm. In this scenario, lifting capacity of 1400mm load will be lower than 1000mm load.

Reference:

Reference:

- Hinz, P. (2018, February 19). Forklift Load Centres Explained. Adaptalift.

- Thill, K. (2020, December 28). The Forklift Load Center: Working with Gravity. Toyota Lift Equipment.

- PHL. (2021, May 19). What are Forklift Truck Load Centres?

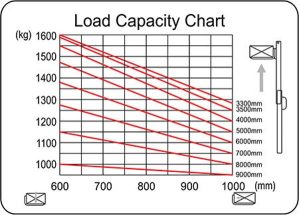

Always remember in mind, there are 2 main factors that will affect the load capacity. First, the load centre. The load capacity will decrease when the load carried is longer (please refer to the Question 4 for detail explanations). Second, the lifting height. The higher you carry the load, the lower the capacity you can achieve. To understand more, I will explain by using the below load capacity chart.

Load Centre

If your load is 1200mm depth (load centre = 600mm) and lifts up to 6000mm, the load capacity is around 1380kg, on the other hand, if your load is 1400mm (load centre = 700mm) and lifts up to same height of 6000mm, the load capacity will drop to 1310kg.

Lifting Height

If you have 2 loads, both having the same load size which 1200mm (load centre = 600mm), but one has to lift up to 7000mm and one has to lift up to 9000mm. What will happen to the load capacity?

For 7000mm lifting height, the load capacity is up to 1220kg. While for 9000mm lifting height, the load capacity is drop to 900kg.

Reference:

- Professional Forklift Engineering Services. (2020, October 30). Forklift Safety: 5 Factors That Reduce Lifting Capacity. Blog | Lift Truck Capacity Calculator.

- Hercrentals. (2019, November 1). Understanding Forklift Capacity. Herc Rentals Blog.

- Ahmed, W. (2021, October 8). Understanding Forklift Load Capacity. Linkedin.

No. There are various masts exist in the market. However, selecting a mast is ultimately depends on your application and how high it needs to go.

Standard Mast

Also known as simplex or V mast. Simplex mast is a two stages mast that without free lift, which means once the fork is raised, the inner mast channel will be started to extend. In terms of application, the standard mast has limit lifting height as compared to other masts but it works best with outdoor operation where overhead clearance is not a concern.

Duplex Mast

Known as FV mast. Unlike standard mast, duplex mast is a two stages mast with free lift, which means the forks can be raised without immediately protruding the inner mast channels. Duplex mast is suitable to use for applications like cross-docking or indoor jobs where the overhead clearance is limited.

Triplex Mast

Known as FSV mast. Triplex mast is a three stages mast with free lift, which allows greater lifting height as compared to duplex mast. It is best to use in warehousing and logistics that required above average heights.

Reference:

- Schwob, J. (2019, January 11). What Are FSV Forklift Masts and FV Forklift Masts? We’ll Explain V and QFV Masts as Well. JIT Toyota-Lift.

- Starke Material Handling Group. (2019, March 15). Forklift Mast Types.

- FLC. (2019, August 27). Warehouse Equipment: Types of Forklift Masts | ForkliftCertification.com.

To maintain the forklift in well condition, it is a must to follow the manufacturer’s recommended maintenance schedule. For example, diesel forklift required maintenance and service very often (every 250 to 300 hours) as it composed of a lot of mechanical parts. For electric forklift, depending on whether it’s powered by lead acid or lithium-ion battery. If lead acid battery, it requires daily maintenance like checking the battery water and topping up if not sufficient, while for lithium-ion battery, it basically has zero maintenance. However, as a recommendation, operator should carry out truck inspection before the shift starts to ensure the truck is in good condition.

Reference:

- Multico Prime Power Inc. Philippines. (2022, March 9). 6 Frequently Asked Questions (FAQ) About Forklifts.

- Wofford, J. (2021, May 24). How Often Should a Forklift Be Serviced? Lilly Company.

- G. (2019, October 1). How Often Should a Forklift Be Serviced, and Why? Aussie Forklifts.

Basically, both electric and diesel forklift do the same job, what separate them is the usage. For diesel forklifts, they are bigger in size and mostly used in outdoor, however, for electric forklifts, they are more compact in size and have smaller turning radius which make them suitable to use for indoor operation. Electric forklifts are powered by battery; therefore, they do not emit harmful fumes as what diesel forklifts do, making them more environmentally friendly. Just to explain a bit further on electric forklift, there are currently two types of battery that being used, one is lead acid battery (traction battery); one is lithium-ion battery. A quick comparison between these two batteries is tabulated as follow:

Lead Acid Battery | Li-ion Battery | |

Life cycle | 1200-1500 cycles | 4000 cycles |

Charging time | 8-10 hours | 2-3 hours |

Maintenance | Require regular cleaning and topping up battery water | Zero maintenance |

Opportunity charging | No | Yes |

Emission of poisonous gas during charging | Yes | No |

Cost | Lower initial cost | Higher upfront cost |

Reference:

- CertifyMe.net. (2019, December 26). Diesel Forklift or Electric Forklift, Which to Use?

- C. (2022, February 3). Benefits of Buying an Electric Forklift vs Diesel Fuel Forklift. HC Forklifts UK.

- Arnold Machinery Company Material Handling. (2022, February 21). Diesel Forklifts vs. Electric Forklifts. Arnold Machinery.

Don’t worry. We would get the suitable attachment to be installed on the material handling equipment, depending on your application, load types and etc. There are various attachments in the market, however, each attachment has its own function. Below explained few attachments that commonly used.

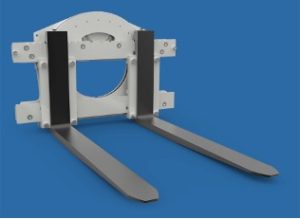

Paper Roll Clamp

| It is specialized for paper industry to clamp the paper roll without damaging or crushing the products. |

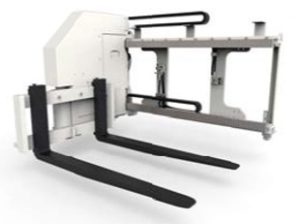

Rotator

| It allows the forks to be turned in 180º and 360º, so that the loads can be dumped into other containers. It is commonly applied for waste and recycling, food processing and agriculture industry. |

Drum Handler

| It provides efficient transport solution for drums and barrels. It facilitates easy picking, moving and placing the various types of drums includes steel and plastic drums. It is commonly used in chemical and petroleum industries. |

Bar Arm Clamp

| It is mainly used in textiles industry where the rolls of cloth are fitted on the bar arms, allowing the rolls to be transported quickly and easily. |

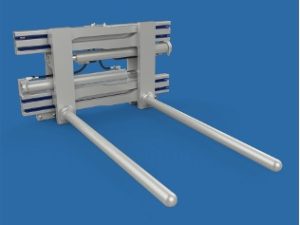

Trilateral Head

| It is an effective solution for handling pallets in a very narrow aisle racking system. It features a traversing fork, allowing you to retrieve pallets from shelving while your truck remains at a 90º angle to the load. |

Reference:

- Lifting Equipment Store. (2021, July 28). What Are Forklift Attachments and How Do They Work | Lifting Equipment Store.

- K. (2022b, April 6). The Types and Applications of Forklift Attachments. LiftOne.

- Toyota Forklifts. (2021, September 29). Selecting the Best Forklift Attachments for Added Use.

- Impact Handling. (2019, May 31). 7 Most Common Forklift Attachments Explained.

- Sunstream Industries. (2019, April 4). Trilateral Head.

The answer will be definitely a yes. Basically, MHE is used throughout the entire chain of physical movement and storage of goods, starting from raw materials to finished goods as well as transport and distribution. Let’s take manufacturing industry as an example. During raw material and production stage, forklift or pallet truck is being used to move materials from one point to another. When the goods are ready (finished goods), reach truck or stacker is used to store the finished goods on the racking. When comes to goods distribution, forklift is used to load the finished goods to the lorry or container and shipped out to their customers. In short, MHE is required throughout the supply chain from manufacturing, warehousing, to logistics

Reference:

- H. (2019, November 7). Understanding the Applications of Material Handling Equipment in Different Industries. Holloway Houston, Inc.

- Menon, H. (2021, August 11). List of Warehouse Material Handling Equipment (MHE) Used for Cargo. Marine Insight.

- Nopper, N. (2020, August 17). The Uses of Forklifts, and Why You Need One. Lakeport Metalcraft Inc.